Character description

|

Projects |

Explain |

|

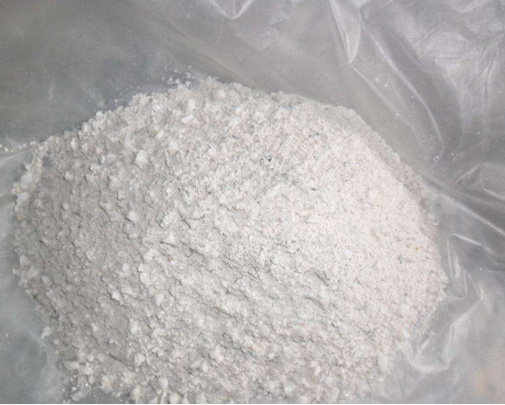

Appearance |

powder-like |

|

Color |

white |

|

Packing |

25 kg moisture-proof bag |

|

Security |

Non-toxic and non-flammable |

|

Storage |

Drying and Sealing |

|

Quality guarantee period |

one year |

Instructions

AM-90 is recommended for ladle bottom or impact plate, seat brick and other materials. AM-75 is recommended for ladle wall and other materials.

|

Material Science |

Specifications |

Ratio(%) |

|

Corundum + magnesia |

<20mm |

80 |

|

Aluminum-rich spinel powder |

AM-90/75 |

15 |

|

Pure calcium aluminate cement |

SECAR 71 |

4 |

|

Superplasticizer |

HDA-1 |

1 |

When the above formula is used, the amount of water added is 3-4%.

The aggregate can be brown corundum, white corundum or plate corundum, and some magnesia can be added.

When using this product, we should pay attention to damp-proof, and stop using it when there are large and hard cakes.

Method of application

Mix the product dry with other ingredients and mix evenly. Forced mixer should be used for mixing. Dry mixing time is recommended not less than 3 minutes.

The total wet mixing time should not be less than 6 minutes after the dry mixing.

Addition amount

The amount of aluminium-rich spinel powder is 10-20%, and the recommended amount is 15%. Users can determine the optimum dosage according to the proportion and raw material self-test.

Important clause

The refractory castable is a multi-element system, and there is interaction between other raw materials and production process and this product. Before using this product, please do the cooperation test by yourself!